Pipeline Integrity Inspection Services (PLI)

Loenbro’s Inspection Pipeline Integrity program assists pipeline owners in ensuring environmentally safe operations while adhering to regulations.

IN-LINE INSPECTION (ILI) VERIFICATIONS USING OUR EXPERIENCED EXPERTS.

Loenbro’s non-destructive testing (NDT) technicians have considerable experience in verifying in-line inspection (ILI) on commonly used smart pigs, including ultrasound (UT) and magnetic flux leakage (MFL) technologies. Our pipeline integrity technicians undergo specialized training and rigorous testing to demonstrate their expertise and precision in conducting these assessments. We are always looking for the latest and most precise inspection methods. Our most frequently requested inspection services include:

-

Phased Array Ultrasonics (PAUT)

-

Full Matrix Capture / Total Focusing Method (FMC/TFM)

-

Laser Profilometry using the Creaform HandyScan

-

Digital Pit-Gauging

-

Ultrasonic Thickness Testing

-

Magnetic Particle Testing

-

Customizable and Detailed Reporting

CONSISTENCY & EFFICIENCY IN EVALUATIONS ALONG WITH RELIABLE RESULTS.

Loenbro’s PC-2 Procedure was specifically developed for ILI verifications. Our technicians are well-equipped and experienced to evaluate all common pipeline anomalies, including, but not limited to:

-

Long Seam Defects (ERW Weld Inspections)

-

Cracking – Including HIC/Step-Wise Cracking

-

Stress Corrosion Cracking (SCC)

-

Corrosion

-

Erosion

-

Pitting

-

Dents

-

Gouges

-

Kinks / Ripples

-

Base Metal Discontinuities (Surface Laps, Slivers, etc.)

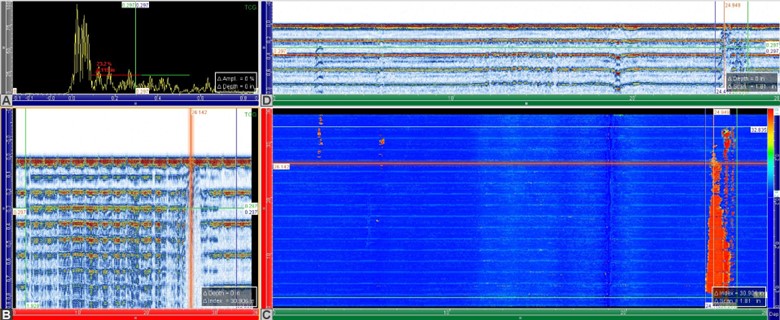

TFM IMAGE FROM CRACKING IN A LONG SEAM

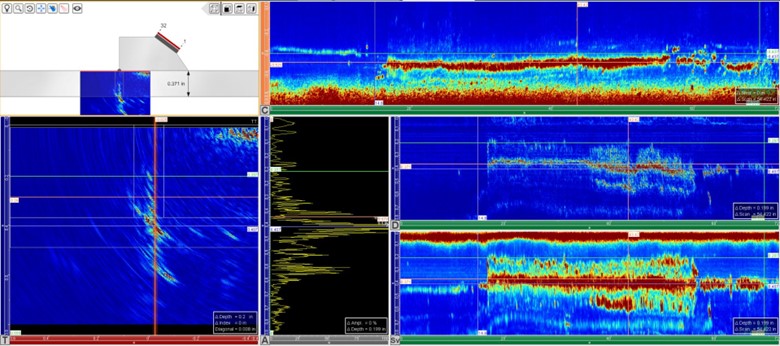

TFM IMAGE OF SEAM UNDERTRIM

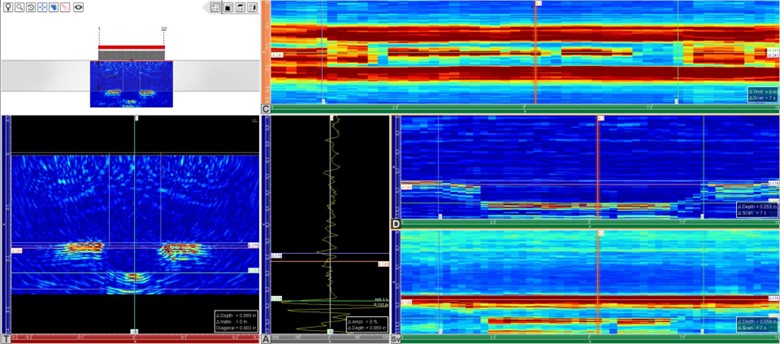

PAUT IMAGE OF AN INTERNAL BLISTER