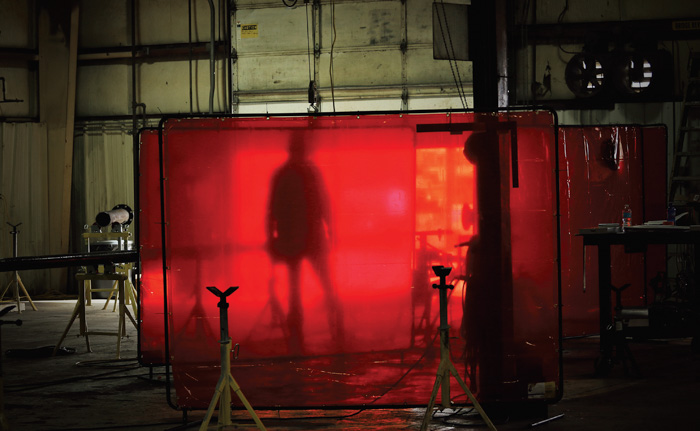

FABRICATION SERVICES

We specialize in precise custom fabrication for our valued customers. From the beginning, we have specialized in producing piping spools, pressure vessels, structural steel components, misc metals, electrical components, and fully developed skids for clients who rely on our commitment to providing the finest available products at the speed and quality that are required.

Advanced Custom Fabrication Capabilities

Custom Fabrication Solutions. Built with Precision. Delivered with Confidence.

Loenbro oversees the entire custom fabrication process, from material procurement and precision fabrication to rigorous quality control, logistics, and final commissioning, ensuring turnkey solutions that meet the highest industrial standards. With over 500,000+ square feet of fabrication space strategically situated across the United States, we are equipped to deliver consistent, code-compliant, high-performance components for industrial projects of every scale.

Founded on a legacy of ASME- and API-certified welding, we’ve expanded our capabilities to include electrical fabrication, modular systems, ASIC fabrication, and high-purity fabrication, giving us the versatility to meet complex project demands.

Our services include:

Process Piping Systems & Modular Assemblies:

Loenbro’s piping fabrication capabilities, both in-shop and onsite, deliver precision-built piping systems and modular assemblies designed to meet the demands of complex industrial environments, using our techniques tailored to customer needs.

-

Carbon & Alloy Piping Spools

-

Modular Skid Piping

-

Process Piping

-

High-Purity & Sanitary Welding

-

LACT Units

-

Launchers & Receivers

-

Underground Duct Bank Modules

Structural & Custom Steel Fabrication:

Loenbro delivers dependable structural and custom steel fabrication solutions designed to meet the demands of industrial and commercial projects, including:

-

Steel Framing for Industrial & Commercial Buildings

-

Pipe Racks, Hangers & Support Structures

-

Hoppers, Extractors, and Specialty Components

-

Modular Process Skids

-

Equipment Stands

-

Platforms: Carbon Steel & Stainless Steel

-

Miscellaneous Metals

-

Process Piping Custom Configurations

Electrical Fabrication:

Loenbro’s electrical fabrication services provide safe, code-compliant solutions, from UL-listed panels to complete lighting and power packages, built to perform in demanding industrial environments.

-

UL-Listed Panels

-

Custom Electrical Enclosures

-

Lighting & Power Packages

-

Medium Voltage Switchgear

-

Low Voltage Switchgear

-

Temporary Power Skids

-

Motor Control

Pressure & Process Equipment:

From certified pressure vessels to advanced welding processes, Loenbro delivers reliable pressure and process equipment built to meet the highest standards of safety and quality.

-

ASME-Certified Pressure Vessels

-

Heat Treating (Stationary & Mobile)

-

Orbital Welding

-

GTAW, GMAW, FCAW, SMAW Processes

Expertise Across Materials

Loenbro’s custom fabrication capabilities extend across multiple materials, including carbon steel, stainless steel, and specialty alloys. Our skilled technicians ensure that each material is carefully selected and processed to meet the highest industry standards for durability, strength, and compliance.

Fabrication Process & Facility Capabilities

Loenbro’s fabrication shops are built for performance, efficiency, and safety. Each facility is equipped with:

-

Overhead & Gantry Cranes – For safe and efficient material movement

-

Onsite Welding Machines & Positioners – Multiple sizes for all project scopes

-

Segregated Carbon & Stainless Steel Welding Bays – Preventing cross-contamination

-

CNC Equipment, Band Saws, Punches & Shears – Precision fabrication tools

-

Plasma Cutting Tables – For accurate, high-speed component creation

-

Post-Weld Heat Treating Ovens – Ensuring metallurgical integrity

-

Full Smoke Evacuation System – For safe indoor operations

-

Hydro Testing (B31.1 & B31.3) – Facility and field pressure testing capabilities

-

Sandblasting & Industrial Coating – Epoxy, urethane, enamel finishes; NACE-certified

-

Material Laydown & Staging Areas – Supporting organized flow of work

-

Mobile Equipment – Forklifts, loaders, and handling systems

Certifications & Compliance

Our team is proud to be a fabricator holding critical certifications that ensure every weld meets the highest standards. Backed by a fully staffed Quality Assurance and Quality Control department, our certified welding procedures and code-compliant practices guarantee consistent, reliable quality, from initial fabrication through final inspection.

Our industrial fabrication services support a wide range of sectors, enabling critical infrastructure and operations across industries such as Oil & Gas, Power Generation, Mining, Pharmaceuticals, Food & Beverage, and Renewable Energy.

-

ASME U-Stamp – Pressure vessel fabrication

-

ASME R-Stamp – Pressure vessel repair and alterations

-

ASME PP-Stamp – Power piping fabrication

-

AWS Certified Welding Inspectors (CWI) – QA/QC on every weld

-

ASNT-SNT-TC-1A VT II – Visual and advanced testing by qualified inspectors

-

NACE Certified Coating Inspectors – Surface prep and industrial coating expertise

Why Choose Loenbro?

Our industrial fabrication services support a wide range of sectors, enabling critical infrastructure and operations across industries such as Oil & Gas, Power Generation, Mining, Pharmaceuticals, Food & Beverage, and Renewable Energy.

-

One-Stop Fabrication Partner – From design to delivery

-

Multiple Facilities (add interactive map when available) – Regional access, national standards

-

Certified Quality, Backed by Dedicated QA/QC Teams – Every weld, test, and finish is verified to ensure consistent excellence at every stage.

-

Custom Built Fabrication for Complexity – We don’t shy away from the challenging jobs